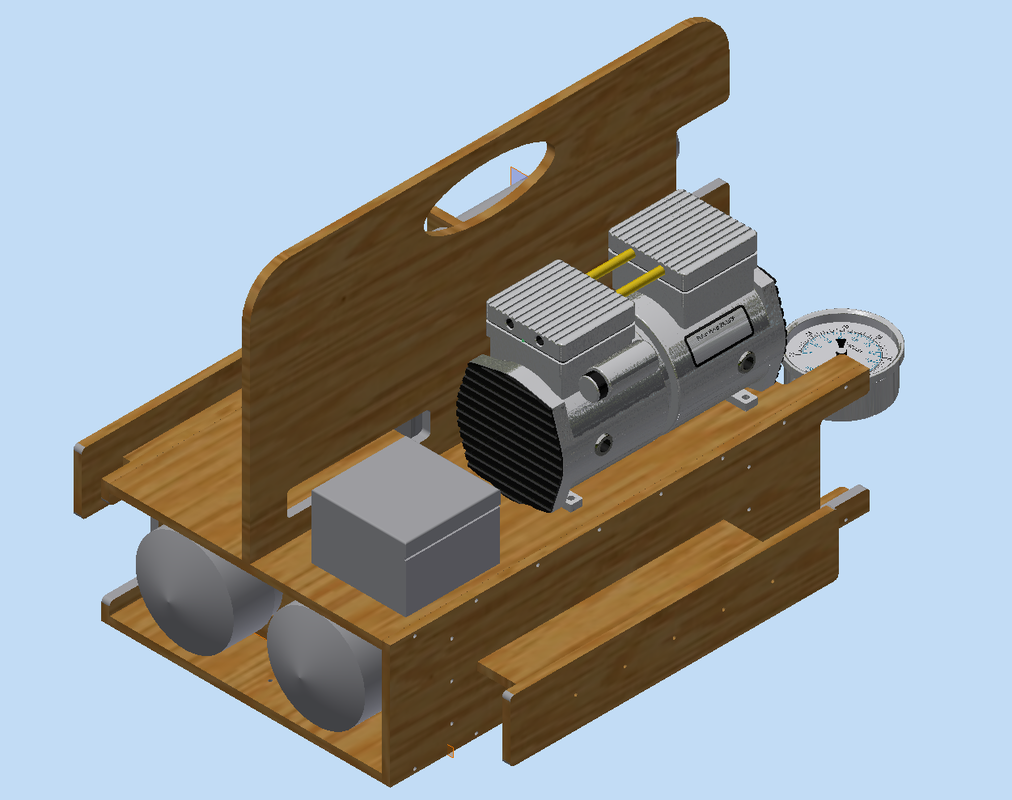

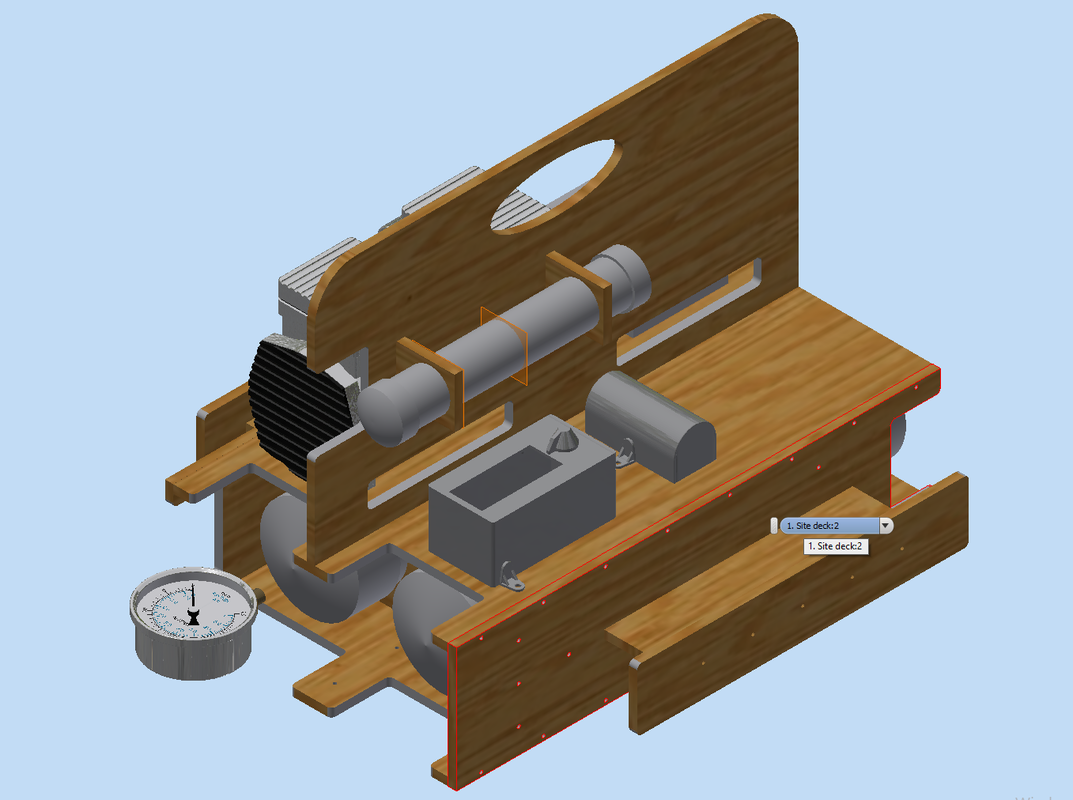

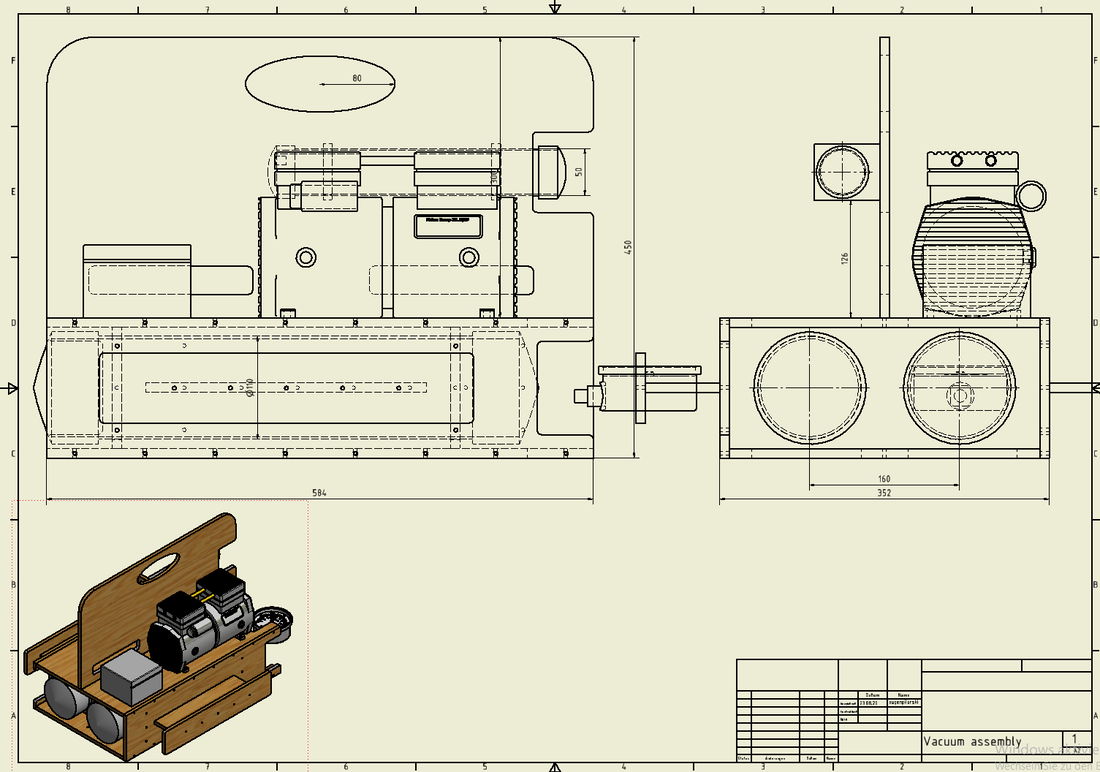

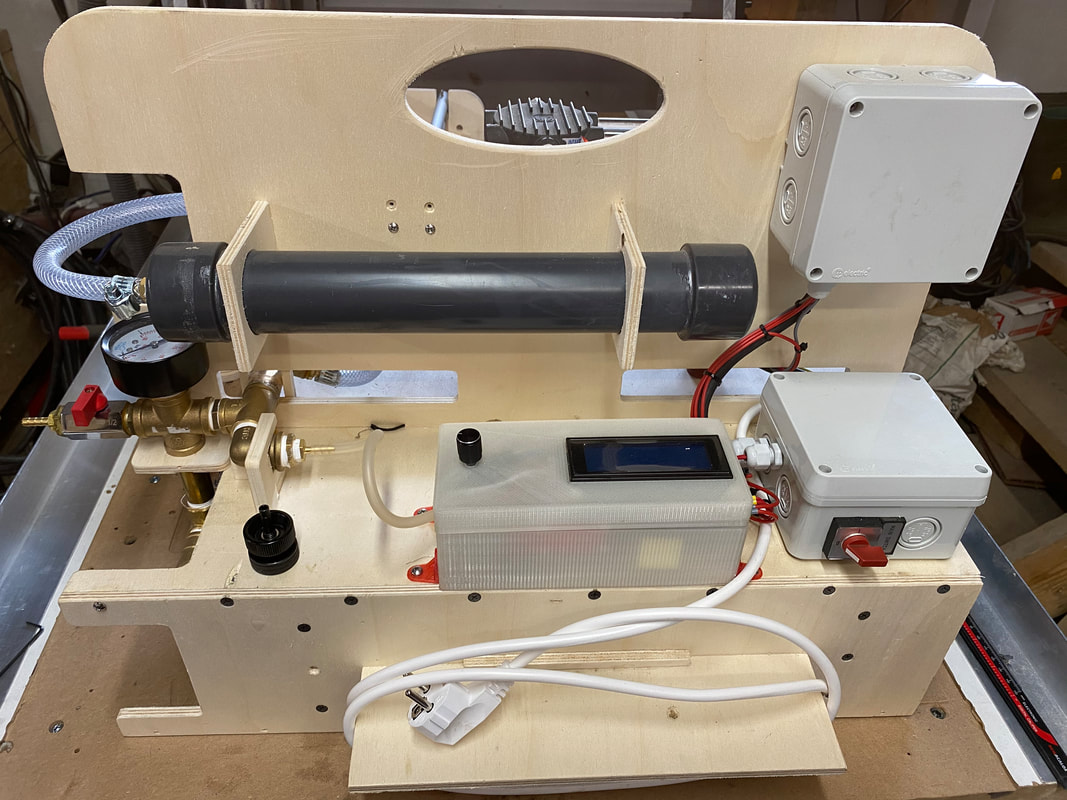

The first step in creating a successful vacuum bagging system is to create a vacuum. We have two options:

For best results, it's recommended that your vacuum pump or generator be matched closely to your project by several factors:

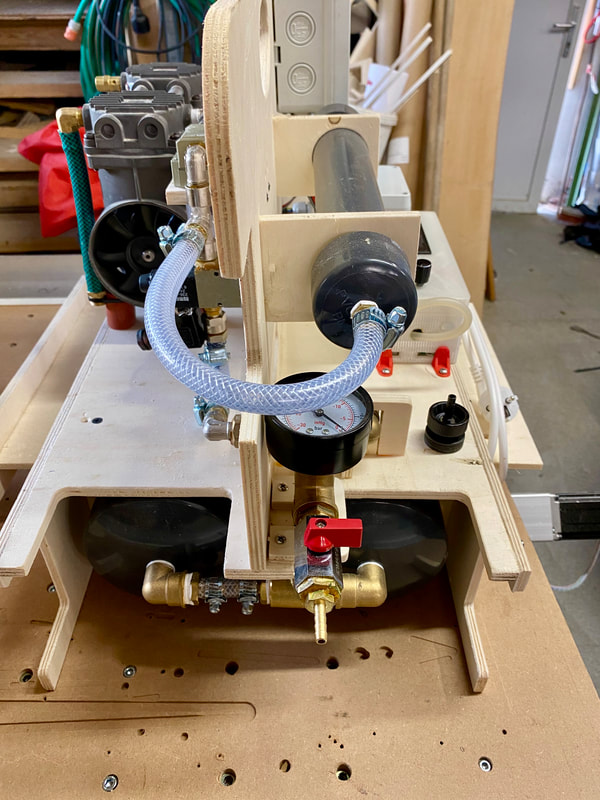

Vacuum pumps are typically rated by four factors:

Vacuum generators connect to an air source (typically an air compressor) and are rated by CFM and maximum attainable vacuum pressure.

All vacuum pumps and generators will require hose assemblies for connection to the vacuum bag.

- a vacuum pump

- vacuum generator that is used in conjunction with an air source.

For best results, it's recommended that your vacuum pump or generator be matched closely to your project by several factors:

- Basic size of pump and part

- Rate of air displacement in cubic feet per minute, or CFM

- Ultimate pressure, measured in inches of mercury, or "Hg"

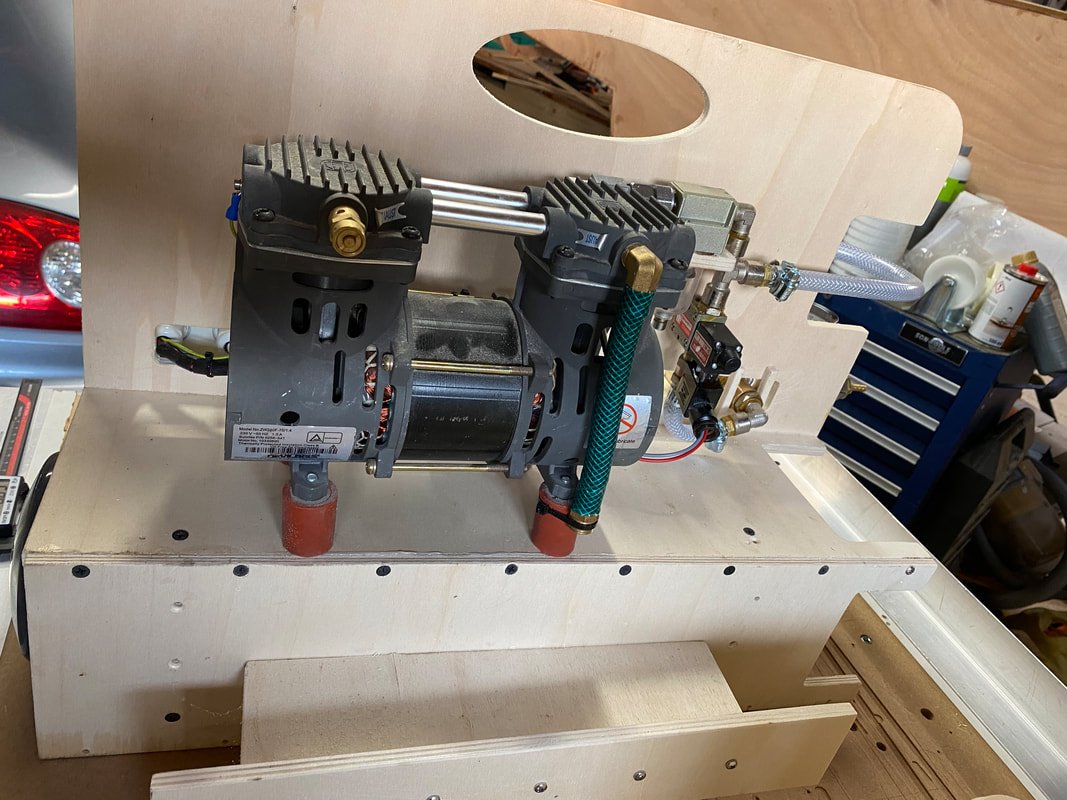

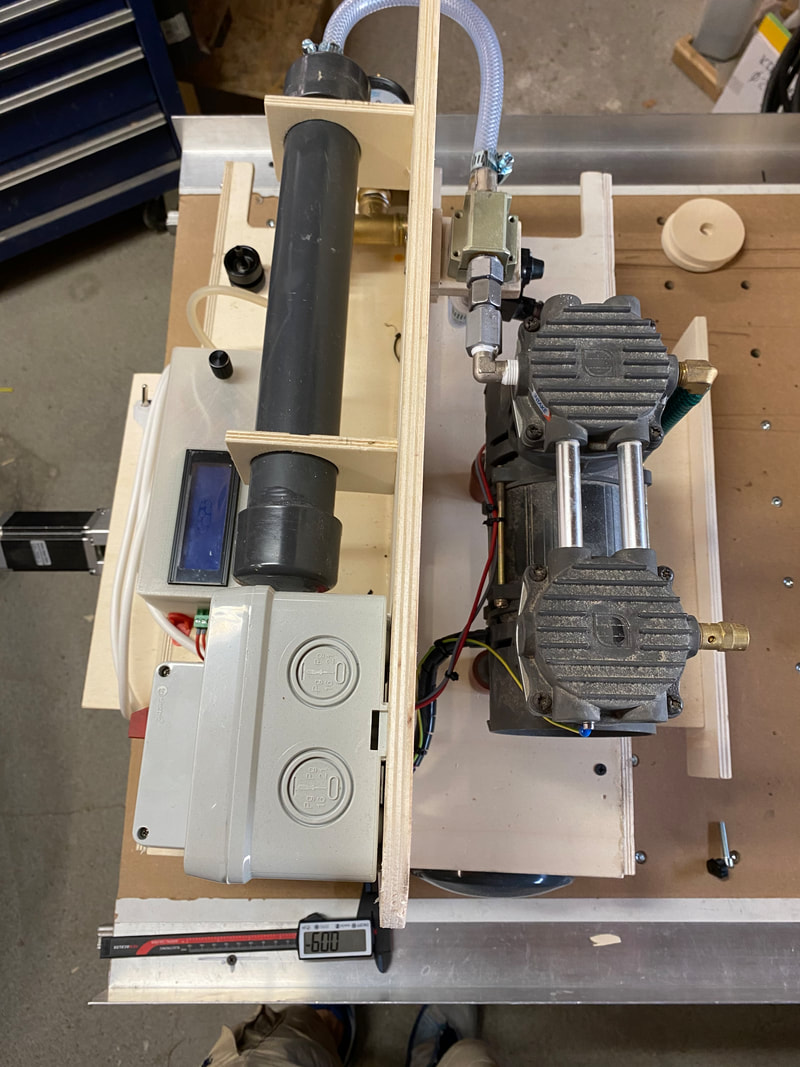

Vacuum pumps are typically rated by four factors:

- the horsepower (hp) of the motor

- the type of pumping mechanism (rotary vane, diaphragm, piston, etc.)

- the volume of air displaced in CFM

- the maximum attainable vacuum pressure in inches of mercury (Hg).

Vacuum generators connect to an air source (typically an air compressor) and are rated by CFM and maximum attainable vacuum pressure.

All vacuum pumps and generators will require hose assemblies for connection to the vacuum bag.