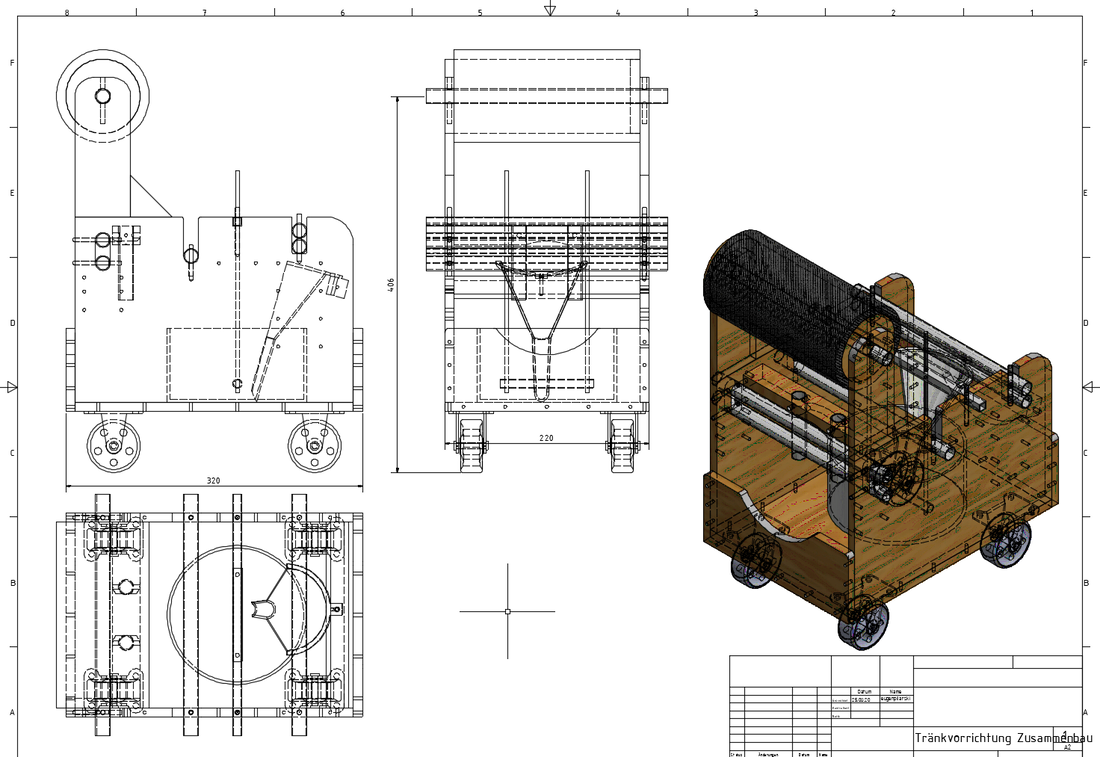

Processing with the aid of simple impregnating systems

Rovings are unidirectional, continuous fibres that are delivered on reels. Rovings are used to draw sections, wind pipes and receptacles, and laminate rein-forcements, e.g. force transfer points.

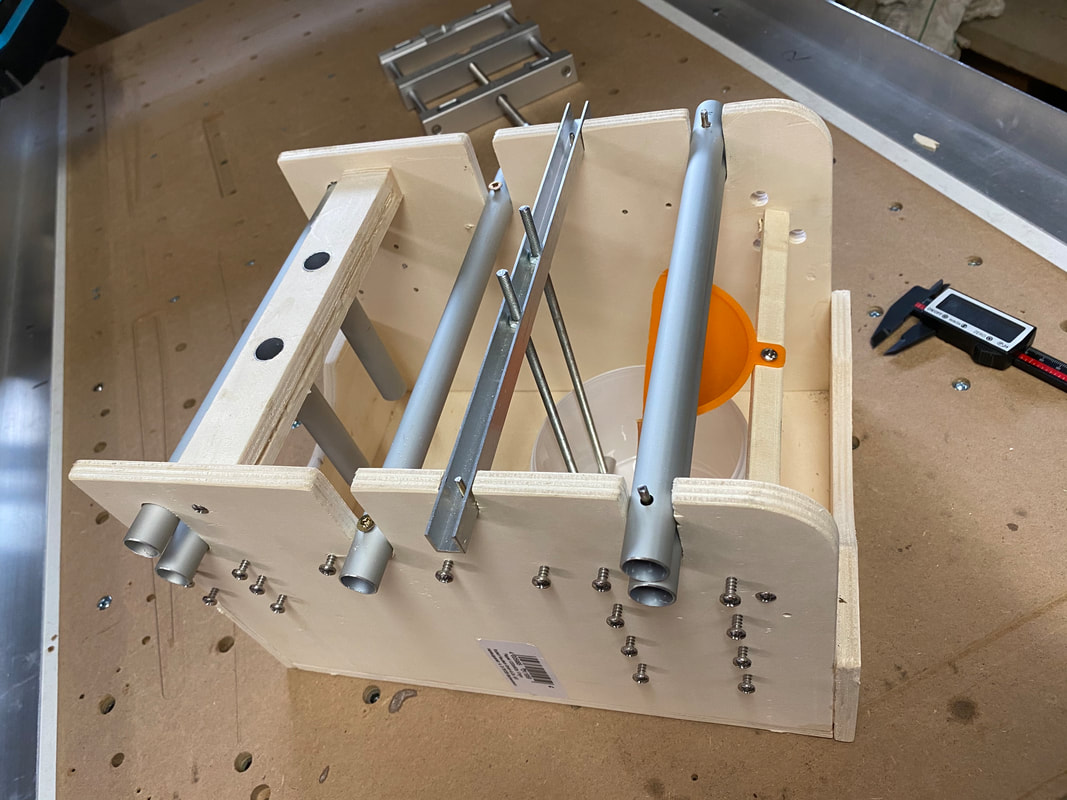

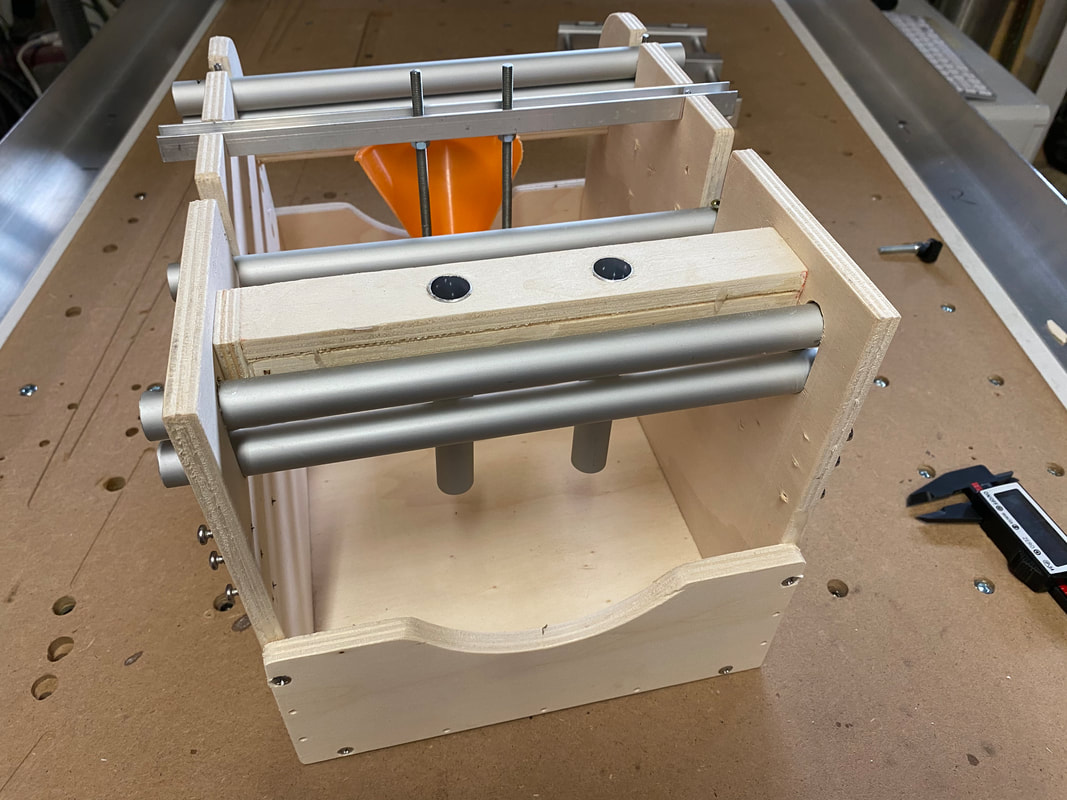

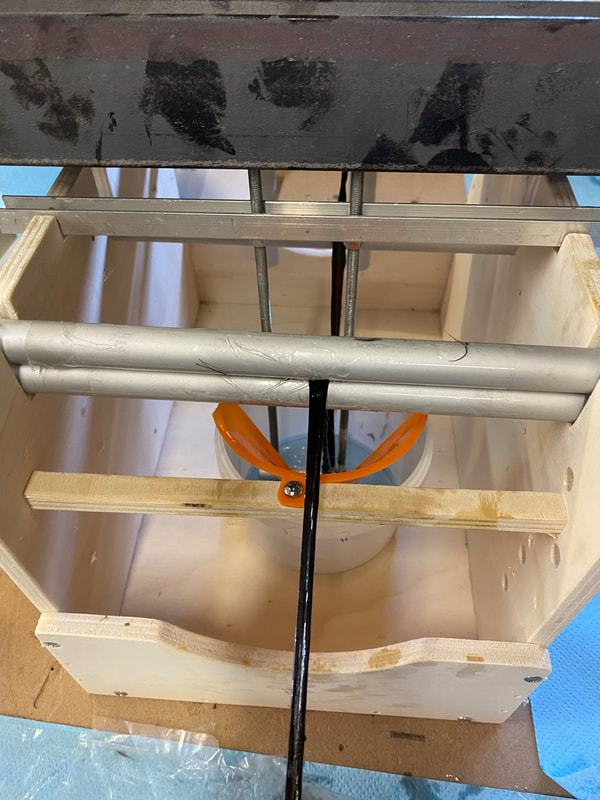

When rovings are used for winding and pultrusion, they are first drawn through a resin bath. Smaller quantities can also be pre-impregnated with a brush on a PE film. Larger components require a roving impregnating system.

The quality of these systems extends from the simplest dipping device that can be made, for example, from small plastic bottles, to complex, heated impregnating baths.

A high quality can be obtained for the component only when the following points are observed.

Rovings are unidirectional, continuous fibres that are delivered on reels. Rovings are used to draw sections, wind pipes and receptacles, and laminate rein-forcements, e.g. force transfer points.

When rovings are used for winding and pultrusion, they are first drawn through a resin bath. Smaller quantities can also be pre-impregnated with a brush on a PE film. Larger components require a roving impregnating system.

The quality of these systems extends from the simplest dipping device that can be made, for example, from small plastic bottles, to complex, heated impregnating baths.

A high quality can be obtained for the component only when the following points are observed.

- The roving must be impregnated uniformly in a low resin content.

- The roving must be stretched during impregnation, if necessary under tension.

Roving impregnating device